These kils need to be on that scaffold… time for some proper work.

I did my first GBBF this year. My first as a volunteer I mean. Except I wasn’t there just to pull some pints, I was attending the CAMRA Bar Management Training that is held at GBBF every year. What is a “CAMRA Bar Manager” – what does this so-called “training” cover? Some would make jokes about beer gut cultivation (doing fine there on my own alas), choice of correct sandals (was a confirmed sandal wearer before I moved to the UK), and beard growth strategies (follicly challenged in the face department alas). Hey, I make fun of CAMRA too sometimes. However, the training really is a good and useful thing for anyone who wishes to care for cask ale – especially in a beer festival environment.

My fellow GBBF Bar Manager trainees.

How do you get to do it?

The training is for CAMRA members and you need to be nominated by your regional director. In my case I was lucky to have been pushed into it along with a colleague from North Herts CAMRA branch because our festivals lacked technical knowledge, plus as of this year we’re running a festival in summer and this requires cooling equipment. Under some guidance I’ve done most of the “cellar” for the last couple of festivals, and looked after the cooling at the last festival. (Luckily we had the GBBF technical director to hand to give us a crash-course.) I say “under some guidance” but there are only a couple of folk in the branch who’s guidance I particularly trust, whilst I’ve had some downright suspect instructions from others! Basically I was a little confused and certainly lacking confidence.

If you’re interested in doing the training I suggest that first you need to be involved with your local branch and have an interest in running festivals. If your branch lacks technical knowledge (many seem to) and you’re keen, you probably have a good chance of getting on the course. (However numbers are limited, so if at first you don’t succeed…). This year the course had people along ranging from 18 years old through to (at a guess) well into their 60s. We only had one woman on the course, which isn’t surprising I guess – is that in line with active membership or below? For my branch it is certainly below. Anyway – one is better than none. The trainees had travelled from all over, a chap even harking from the Isle of Man – plus a dude from the US doing the course as part of some exchange programme.

We learnt how to put together this modular scaffold stuff. (Not rocket science… but there are some tricks to it.)

What is covered?

A suffusion of beer festival information! The course is misnamed in a way. Whilst set-up and care of cask ale was core, we also had sessions on health and safety, risk assessment & insurance, ordering kit from HQ, foreign beer, beer flaws & infections, dispense technicalities (a keykeg made an appearance – yes, they can be perfectly OK as “real ale”), scaffolding, beer logistics & stock management, and cider. So really you could call this a “festival organiser course”, I think I probably could have a go at running a whole festival now (if I was that masochistic).

The course is a mix of theory sessions, hands-on practical sessions, and for the majority of the time plain old hard graft behind a GBBF bar. Every trainee is given to a GBBF bar manager (Buster Grant from Brecon Brewery in my case) and expected to get stuck into all aspects of looking after the bar (whilst trying not to get in the way too much).

Beer nasties under the microscope in the GBBF QA lab. They take this stuff seriously.

GBBF trainee schedule, in brief…

I arrived on Saturday August 10th, signed in and immediately reported to Buster – for the first two days trainees are handed straight over to their managers to provide extra muscle for set-up. First job: kils are arriving on pallets and need to be up on stillage. Cooling was hooked up. Beer lines and pumps set up and cleaned.

A typical GBBF stillage exists in two distinct parts – one is what you see behind the bar: a scaffolding structure with a lower and an upper deck where casks are sitting under cooling jackets. Part of the art of setting this up is deciding where to put the casks in order to aid efficient take-down. I.e. under Buster’s system the 1st and 2nd casks on are all out to the edges so that the outer cooling systems can be broken down early. There is no prescriptive one-way-to-do-things however, and each GBBF bar manager has developed their own methods and tricks. There are some constraints of course, such as: there are typically 4 kilderkins of each beer and these need to be arranged such that the line from a given hand-pump is able to reach them all. (Having done this GBBF I can very much see why kils are a necessity!) [Edit: I forgot to explain the “second part” – this is a huge refrigerated box located behind the stillage that has the other half of the beer in it. Up on a double-layer scaffold. The cooler boxes are much simpler to set up and manage and some think it should all be done that way as it is so much easier – however others think the “look and feel” of a festival is not as good without all the kils out on display.]

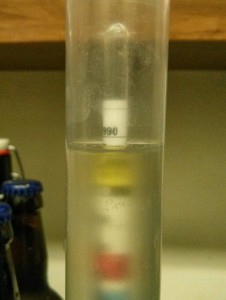

The first casks were vented and tapped on Sunday so they would be ready for the “trade session” on Tuesday. Through the week the remaining casks are vented, tapped, and hooked up to lines as required. Twice a day the volume of beer in the casks that are on is measured with a dipstick and this feeds in to deciding when to vent the next-casks-in-line. When a cask runs dry it is sealed up and moved to “the crypt” at the end of the day.

This all amounts to a truly epic operation. Have a look at the crypt for an idea of the scale of things… (you can drag the image around for a full 360-degree experience… Google did NOT make this easy to achieve!)

The actual coursework and theory of the training is held in sessions from Monday through to Friday. Monday is a quiet day for a good bar team anyway – as most of the set-up is done and it is just a matter of spit-and-polish. A day of rest before the beer-drinking hoards hit the festival on Tuesday. Throughout the weekdays trainees split their time between the sessions and helping out at their bars wherever they can be of use. Everything from beer technicalities to serving customers at the bar – plus quite a bit of mopping at times.

Colin thirsty for hops… enjoying a beer in the Voly after another long GBBF day sitting on my head.

The reward at the end of every night is time for a couple of free pints in the “Volunteers Arms” (aka “the voly”) – the staff-only bar (with over 200 different beers on over the course of GBBF – it is a beer-festival within a beer-festival). It was a long week with post-voly bedtime most nights being about 2AM. However we didn’t need to be on-site until 10AM(ish) so that’s not all that bad.

At the end of the final day, within 2 hours of 5pm “time at the bar”, all casks and equipment were off stillage and on pallets. On Sunday the 18th, my last day, I was mostly in the crypt sorting and stacking dead casks. One final batch of hard graft before scooting home on the train for a much needed night in my own bed before heading back to office drudgery on Monday.

It was a long 9 days – and the seriously hardcore volunteers have a couple more either side to make it about 2 weeks on-site. Dedication to cask ale!

The handpumps of Bar 19.

Cask ale care…

(especially with my own festival in mind)…

All the topics covered interested me. (Well, to be honest: the cider session was a nightmare). But I was really there for the beer. How does one serve cask ale in good form? Unfortunately there isn’t 100% agreement on this! However most disagreement comes down to peripheral issues like whether or not venting tools were good and how you should arrange beers on stillage. The term “dark art” came up more than once. However there was enough of a consensus for me to build up a plan for my next festival. I’m lucky enough to have one that isn’t complex – we have 1 cask of each beer (a mix of firks and kils) and they all go on at once for 2.5 days of service starting Thursday evening. Here’s my rough timeline – feel free to critique it. Please.

- Monday: (preferable) or Tuesday (ASAP) get all casks on stillage and under cooling.

- Would prefer Monday with casks sitting overnight before venting, but that incurs the cost of an extra night of overnight security.

- Conflict exists about whether or not to be variously violent with casks to “redistribute muck and finings”. My position is violence here doesn’t seem necessary. Plus they have already been rolled around the ground quite a bit at this stage.

- Conflict exists here with respect to use of soft/hard pegs. My position is that soft pegs should only be used where casks exhibit excessive activity. Hard pegs should be applied as soon as activity dies down.

- Ideally casks should have a few hours to sit at this point prior to venting.

- Tuesday: vent and tap all casks.

- Hard pegs firmly in all casks unless there is excessive activity.

- Wednesday AM: 1st check of beers.

- If good mark as “OK”, otherwise mark as appropriate – making note of any particular taints or excessive haze.

- Wednesday PM/evening: 2nd check of beers.

- If good mark as “OK”. Any still with with excessive haze that hasn’t changed since the 1st check to be tested for overnight with isinglass and aux finings (if possible).

- Thursday AM: 3rd check of beers.

- If determined that finings should be added to any beers, do it now. Carefully & in-place, using a funnel and bent tube. (This is how it is done at GBBF.)

- Thursday pre-opening:

- Check any non-“OK” beers before opening. Attach/flip their cask-end-cards for “OK” beers. Soft spiles in “OK” casks for duration of service.

- Thursday end-of-night: Stock-take with dip-sticks, and hard spiles in all beers.

- Friday pre-opening: Check any beers not yet “OK”. “OK” them if possible.

- Friday end-of-night: Stock-take with dip-sticks, and hard spiles in all beers, perhaps plastics in any below half-full.

- Saturday pre-opening: Check, “OK”, etc…

- Saturday end-of-night: It’s all over!

- Pack up as much kit as possible before bed as it all needs to be packed and off-site by Sunday arvo.

This isn’t actually a massive change from my usual schedule – but it does contain more detail and care than previously! Any glaring problems in the schedule? Please let me know in the comments or on Twitter… Some trivialities are omitted, it is the general timeline that’s the important part. It contains things I did not do before, such as:

- Much more fine-grained checking of the beer in the lead-up to opening.

- Using finings on beers that really don’t seem to want to drop bright.

- Regular stock-taking throughout the festival (we need a flexi dipstick!)

My primary goal at any beer festival is: serve an enjoyable pint of beer. Sometimes the beer works against you and it seems to be a given that less-than-perfect pints are not unexpected at CAMRA festivals. I wish this were not so. We should be shining a light upon what a good pint of cask ale can be. Alas the beer works against you sometimes. I have had perfectly fine tasting beer arrive dead flat. What do I do then? I’d like to mark it as crap and send it back to the brewer – cue frustrating arguments. If it tastes fine, has condition, but carries a little haze or “cast” (a very very light haze) I put a note on the cask-end card and tell the bar staff to give prior warning along the lines of “it tastes perfect, but has a little haze to it”. (When we have unfined beers this is perfectly OK of course – though this is more difficult to explain to staff, let alone customers!) Anyway – enough of an aside here, this paragraph is what comes from my personal experience prior to GBBF. (GBBF training cannot offer any silver bullets for these issues.)

These are the tools of the GBBF Beer-QA lab. Probably a bit more than I really need…

Tools & Toys…

My branch has a couple of toolboxes. Mostly they’re full of rusting relics. Post-training we’re going to have to audit the selection… and we already have a shopping list! Perhaps more on that another time, “The CAMRA Bar Manager’s Toolbox”?

One interesting point is the obvious issue of returning part-full casks. We just hammer in the hard spile and put a cork in the end. While this is clearly not sufficient to stop beer leaking out I’d figured it was simply “the done thing” as it is the thing that is done. After having worked at GBBF, with an actual brewer as a bar manager, I now know this is one of the things that can make brewers quite grumpy. So… want to keep your friendly brewers friendly? Your festival should have a de-shiving tool and sufficient replacement shives and bungs. Any beers returned with a lot still in the casks should have new shives and bungs fitted and ideally be marked as part-full. If the beers were “wrong” in some way this should be marked in some way too – red tape over the bung helps to identify casks with a possible infection. We shall be obtaining such a tool (a sturdy screwdriver can do the job, but the correct tool is easier & safer) and some bags of shives & bungs.

Featuring “Let There Be Beer” – a travesty.

Finally…

I have great personal conflict & angst over my involvement in CAMRA. On the one hand I think cask ale is great and worthy of advocacy, I love the CAMRA community, and I love being involved in and going to beer festivals. On the other hand I have found the organisation’s vague support for pubs disheartening – though that seems to have improved greatly in the last year. I’m regularly angered over CAMRA’s willingness to be an advertising-front for JD Wetherspoon and their friendliness with some “brewers” who’re also actively destroying pubs. More recently, I’m really irate about their ill-conceived involvement with this whole Let There Be Beer shambles. LTBB is primarily (solely) promoting big-brand beers available on the cheap from your local supermarket. This does nothing for cask ale and is actively anti-pub.

I swing between really enjoying being a part of CAMRA and feelings of ARGH, CAMRA! *angryface* I QUIT! (╯°□°)╯︵ ┻━┻

I have, quite inaccurately, split the target of these feelings between “what normal CAMRA people do” and “what HQ decides”. HQ gets the anger pointed in their direction and meanwhile I get on with beery things with the normal CAMRA folk. The ones who love beer, enjoy beer festivals, and mostly just want to have a good time. Whilst doing so they hope that they can help others discover the beer they love to drink and ensure its availability in the future. We are volunteers putting our own time into something we love. GBBF is the product of 10s of thousands of hours of volunteer time – I can’t help but be impressed by that, and be proud to have been a member of the 2013 GBBF team.

I’ll be back.

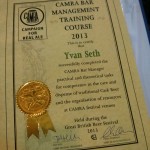

I did it all for this – I’m official now. Look – it has a shiny sticker on it!

Complete photo-set:

-

-

The sun sets on GBBF 2013 – see you again in 2014 Olympia.

-

-

We’ve finished our work here – the scaffolding is now in the hands of the site team.

-

-

Brewers give us free shirts… but tend to come in L, XL, XXL, XXXL, XXXXL, Darts Player… but not SMALL!

-

-

I did it all for this – I’m official now. Look – it has a shiny sticker on it!

-

-

Caption competition perhaps?

-

-

GBBF Bar Staff

-

-

The handpumps of Bar 19.

-

-

Beer nasties under the microscope in the GBBF QA lab. They take this stuff seriously.

-

-

These are the tools of the GBBF Beer-QA lab. Probably a bit more than I really need…

-

-

Colin thirsty for hops… enjoying a beer in the Voly after another long GBBF day sitting on my head.

-

-

The Champion Beer of Britain queue for the 1st public session – on our bar! Elland’s 1872 Porter.

-

-

These chaps were first in the queue for the champion beer of Britain.

-

-

We learnt how to put together this modular scaffold stuff. (Not rocket science… but there are some tricks to it.)

-

-

No nasty CO2 at GBBF – kegs are pressurised with good old “air”. Hm. Fine so long as beer sells FAST.

-

-

They’re kept in a rather cold cooling unit and sell fast enough that they can sit out in the room and be pressurised with air rather than CO2.

-

-

Buster, bar manager of B19, and my primary practical instructor for the training. Buster is Brecon Brewery.

-

-

The Jolly Brewer – aka B19 – aka Buster’s Bar. My GBBF home.

-

-

Olympia is a joy to behold… but it gives me nasty flashbacks to 1st year civil engineering. I feel like I should be calculating the forces in all those struts!

-

-

Featuring “Let There Be Beer” – a travesty.

-

-

My fellow GBBF Bar Manager trainees.

-

-

These kils need to be on that scaffold… time for some proper work.