Don’t try to define craft beer, that way madness lies… [Added 3/8/15 21:41: Please don’t read this as me insisting there ought to be some sort of an enforced definition… nor that I think I am laying down a One True Definition of Craft… it’s just a thought exercise. I do still think the concept is worth pondering.]

But hey, everyone seems to be defining craft beer again. I decided to give it a ponder, to flog the dead horse per se. Nowt better than a well flogged equine corpse. (I clearly don’t have enough to do… like accounting, inventory, and sales for example.)

The problem is nearly every definition goes into some wishy washy non-measurable territory about “quality” and ethos. This isn’t going to work… after significant thought (5 minutes, but on the back of several-years worth of feedback loop), here’s what I boil it down to from my own personal perspective. This is _my_ best attempt at a definition of “craft beer”, it gels with a lot of others, even BrewDog’s, but brings in stricter ownership rules and discards what I see as unnecessary minutiae & subjectivity.

- Brewery is “privately” owned and controlled.

This is about being in control of creative direction, not being answerable to shareholders and investors. Freedom. Being an exchange listed company _definitely_ rules you out of the “craft beer club” (which, to my pleasure, takes Greene King out of the definition, huzzah!). Collective employee ownership is OK however – that’s about as craft as you can get I reckon. You can buy a brewery and have it still be craft too, so I’m not tying this down to founder-owned. Look at breweries like Moor, for example. [Disclosure: I sell Moor beer. It is awesome.] I’ll allow breweries owned by rich benefactors as well, so long as they have entire ownership of the brewery, so I’m not tying it down to brewer-owned either. If the owner(s) build it up, and sell it to Molson Coors… craft status stripped. Harsh perhaps, the beer probably won’t change in the short run (it will almost certainly change in the long run). But I believe craft is about more than the liquid in the glass.

- Investment companies / investors own, collectively, no more than 10%

I think equity-investment in brewing is fine, see “rich benefactor” above, but a large corporate or institutional investor pretty much says one thing to me: where’s the exit strategy? It isn’t quite universal, perhaps, but it is nearly always the case that investment means travelling a path towards a destination of either sell-out-high or get-listed. Cash-in, cha-ching… that’s not craft. On the other hand, making lots of money by building a mega-successful brewery is perfectly OK. It’s “selling out” that I don’t believe is craft, unless the “sell out” is privately to a private owner in which case there’s room for the operation to remain “craft”.

Beer clearly states origin and name of origin brewery.

Beer clearly states origin and name of origin brewery.

Origin fudging is not craft. I won’t budge on this one. Being shy about your production is not craft. If you’re embarrassed about how & where your beer is produced: it is not craft. I’ve no problems with cuckoo or contract brewing so long as it is done honestly – Yeastie Boys are an example of honest (and worthwhile) contract brewing. [Disclosure: Yes, I sell their beer. Because I love the beers.]- Beer lists all ingredients.

At a minimum top level ingredients, including brewing essentials such as yeast – so a list such as: Barley Malt, Flaked Wheat, Hops, Yeast, Blood Oranges, Otters’ Tears. I don’t really understand why this isn’t more normal, in my opinion it ought to be a legal requirement. But failing that – brewers should just naturally choose to do this! If you’re not proud of your ingredients, not ashamed to admit what goes into the beer, than you’re not craft as far as I’m concerned. I’m not saying brewers should give out the recipes to their beers – I am saying every beer should say what is in the bottle. And I want more than most here, as much as is practical. Malt types, hop varieties, yeast strain (and “our house yeast” is fine here). Whether isinglass is used at any stage too. Ideally this should be on the bottle, it can’t practically be presented for keg/cask – and sometimes hops have to change, often recipes evolve, but that’s what websites are for: 8 Wired, Hopwired [Disclosure: Hey, I happen to sell this stuff too.]

- Brewery meets a (to be determined) set of basic standards.

This one needs some work. But, basically, I would lay down a set of minimum standards in addition to the core points above… I don’t think it is good to be too specific, like ruling out use of certain adjuncts, or brewing processes, etc. But there are some basics that are simple to audit. Some rough initial ideas: pays at least living wage (quality of people, I don’t think living wage is perfect but it is a start), invests in cold-storage (quality of beer), deals with wholesalers who invest in cold-storage (self-interest afoot here! But I believe *strongly* in improving supply chain in this direction – and the same applies for exporters and foreign distributors), educates employed brewing staff (owner-brewers excepted perhaps?), does not package beer in clear glass (personal enraged bugbear!) … what else? (All subject to debate…) [I’m, astonishingly, changing my mind on pasteurisation just a little, there are circumstances where I can accept it is not a compromise. Late additions of maple syrup, for example… how’s that for a subject for a “craft debate”?]

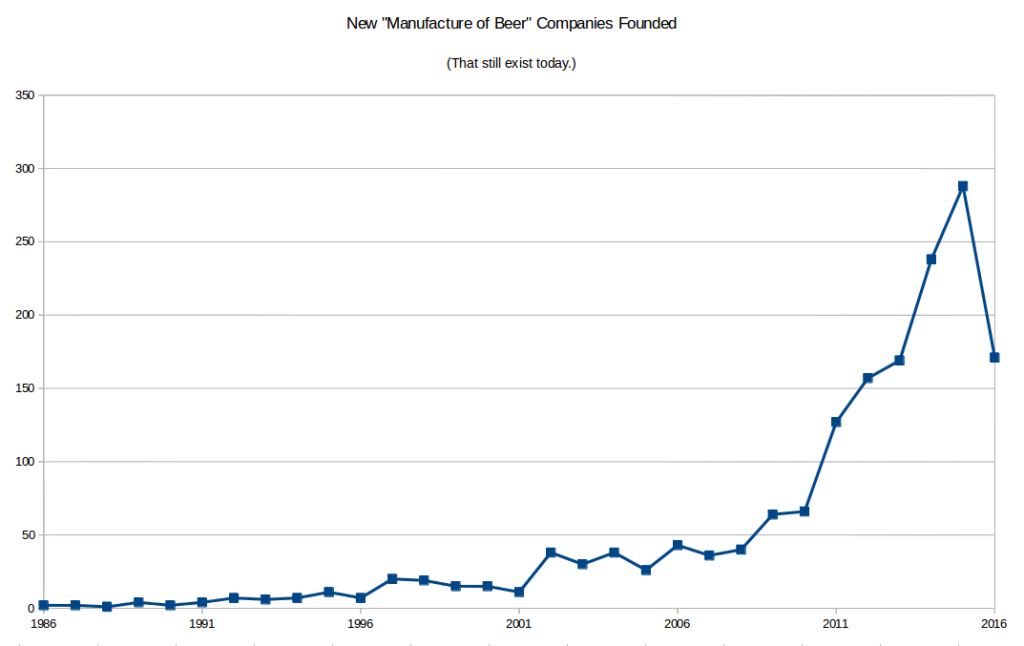

What, nothing about about size? Production volume? Etc… I think the US has shown that measuring craft by brewery size doesn’t work very well.

It may not quite be perfect… but it is “craft” as I see it, as much as I can pin it down within my own mind. Plenty of breweries I think are a bit crap fit within the definition, but defining craft beer can’t be about what I do and don’t like and it needs to be objective if it is to work at all. I use the word and if I’m to continue to use the word I ought to be able to outline what I mean when I use it… that’s one of the points of this post.

I’ve an ulterior motive in all this of course. Because I think, if done right, this can be used as a mechanism to drive change and improve quality in the UK beer industry. A proper craft beer representative body can pick up where SIBA fails to deliver, and bridge the gap to where the Beer Academy doesn’t quite seem to have the grunt to execute.

If there is to be a wider crystallisation of a concept of craft then mere definition is not enough… it needs an organisation behind it to work. Sometimes there are grey areas and a committee, perhaps, needs to make a ruling. For a definition to work lines do need to be drawn. And the organisation doing this needs to really stand up for the ethos behind craft beer… creativity and independence, and striving for quality. (We can’t make quality part of the definition, but an organisation can support and encourage it.)

This should be a membership based organisation like SIBA, where all breweries that meet the definition can join for a fairly low fee. (£250?) [But you don’t have to be a member to _be_ a craft brewer!] Major decisions are made on an open democratic basis – we have the technology to achieve this quite simply. The purpose of the organisation is to manage the membership, manage the definition, promote the concept of craft beer, and – importantly – make an attempt at defining best practice. Work to improve and modernise the world of great beer in the UK, which will be of benefit to everyone in the chain from farmer to drinker.

In the UK we’ve a lot to do to improve the pint of beer that ends up in the glass. SIBA isn’t doing it (but it does help), the Beer Academy isn’t doing it (but it does help), CAMRA isn’t doing it (and may actually have become a barrier to good quality).

Finally – “craft beer” should try hard not to look down on “not craft beer”. We’ll all have our own personal prejudices which we won’t give up (*cough*GreenKing*cough*). But we have to accept that some multinationals do make a high quality product, and sometimes it even happens to be rather tasty.

This has been a craft community broadcast brought to you by the vested-interest department… and I may very well change my mind tomorrow. Or after I’ve had a beer.

P.S. In all of this I think it is well worth being aware that craft is not necessarily equal to “good”, and non-craft is definitely not equal to “bad”. Good and bad are subjective and undefinable, there is debate even around identifiable brewing/beer flaws. Craft is not equal to “better” – but it will _usually_ be more interesting than the alternative thanks to the creativity and flexibility of the style of operation I think my above points encompass. Cases in point are to look at Greene King’s efforts at “craft”, and Marston’s “Revisionist” beers… which for the most part I don’t think are _bad_ beers, but they’re clearly contained and restrained beers… yet are the most “adventurous” beers breweries of this scale and shareholder-value maximising sensibilities will produce. (You can still brew really dull beer within the points of my attempt at a definition above, of course.)

Like this:

Like Loading...