In the whole discussion about “the state of the industry” going on lately we see figures bandied about from CAMRA and the BBPA. I like to work some of my own data out from sources where possible… but unfortunately there is no clear source of “number of breweries in the UK”. This quick post was originally a comment on Boak & Bailey’s Beer Blog: Gauging the Mood of the British Beer Scene. But it became a bit too long for something a bit too tangential.

The comment started with me thinking to myself: I would put (not much) money on hitting 2000 breweries this year. I still hear of far more openings and planned openings than closures.

Not much of a stretch on the BBPA’s last figure of 1700 mind, but a bit of a jump from the 1500 I see most often (GBG/CAMRA?)

Where do they get the numbers from?

You can download all Companies House data here: http://download.companieshouse.gov.uk/en_output.html

It is mahoosive of course – 5 separate zip files, about 1.5GB data uncompressed. (Fully shut down companies are not listed.)

You can count the number of ‘Active‘ entries marked as being in the business of ‘Manufacture of beer‘ (including as non-primary business)… the number is 1645… which seems “sane”. Some of which are likely bogus like the “Gourmet Jerk Chicken Company“. And bear in mind some breweries may be sole traders or partnerships not registered with Companies House so they will not show up in this data. I guess what we want to know really is from HMRC how many registered for beer duty are reporting a non-zero volume brewed – they’ll be the truly active breweries.

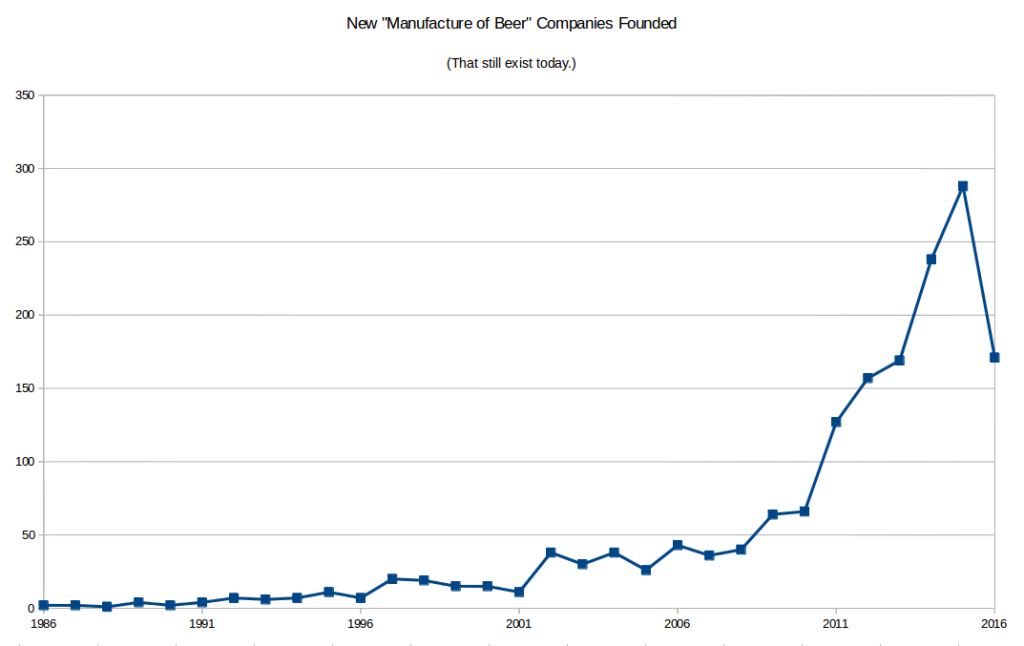

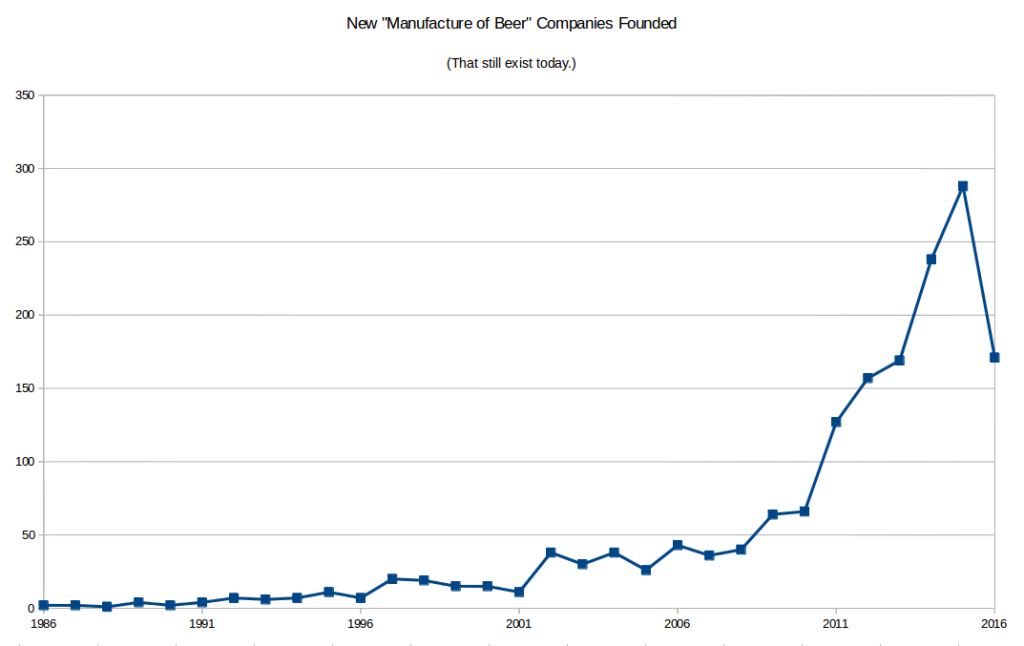

You could filter by date and see how many companies have been registered each year with the intention of being in the “manufacture of beer“. In 2016 this is 171 new companies formed with this intention. Bear in mind that we don’t know how many of these have gone on to be bona fide duty registered breweries. In fact how about the last 3 decades?

| Year |

New Brewery LTDs

(Still Active) |

| 2016 |

171 <- suspect |

| 2015 |

288 |

| 2014 |

238 |

| 2013 |

169 |

| 2012 |

157 |

| 2011 |

127 |

| 2010 |

66 |

| 2009 |

64 |

| 2008 |

40 |

| 2007 |

36 |

| 2006 |

43 |

| 2005 |

26 |

| 2004 |

38 |

| 2003 |

30 |

| 2002 |

38 |

| 2001 |

11 |

| 2000 |

15 |

| 1999 |

15 |

| 1998 |

19 |

| 1997 |

20 |

| 1996 |

7 |

| 1995 |

11 |

| 1994 |

7 |

| 1993 |

6 |

| 1992 |

7 |

| 1991 |

4 |

| 1990 |

2 |

| 1989 |

4 |

| 1988 |

1 |

| 1987 |

2 |

| 1986 |

2 |

If this data is accurate in 2016 that could be quite interesting. (I wonder if there is any lag in registrations showing up?) [According to comment from MarkB below there probably IS a lag in the companies house data.] It could indicate 2015 was a peak in founding breweries. But we don’t have anywhere near enough data to come to that conclusion with much confidence. I would now be unlikely to bet on us hitting the 2000 brewery figure this year. This post is a bit drab, so how about I graph that too:

You can also grep the file for things like ‘Liquidation‘ (there are other relevant states to examine) to see who’s marked as such by Companies House right now. (As of 1st January, say.) Bearing in mind companies can be in this state for months, years even. There are 33 in “Liquidation” right now – but including many most of us are aware of (and reasons for liquidation can be fairly benign I think), and there are red herrings aplenty so the data needs a careful cross-referencing.

There’s quite a few marked ‘proposal to strike off‘ – worth investigating (sometimes just because of badly run businesses tardy with filings?). And a handful in Administration or a Voluntary Arrangement, some I’ve never heard of others much higher profile.

This is just snapshot in time mind.

Someone seriously monitoring this stuff could download the data monthly and map some trends. But I suppose that what people at companies like CGA Strategy are paid to do for us, so we can buy expensive reports every year! (I don’t, I can’t afford expensive reports.)

But anyway, here’s a whole data project for some beery data-nerd. In a former life I’d have started doing something with this….

Here’s the 2017-01-01 data filtered down to just ‘Manufacturers of beer’, which is a much more digestable 119kB: brewers-basiccompanydata-2017-01-01-csv

Like this:

Like Loading...