The BIIAB ABCQ is the UK’s only professional qualification for cellarfolk as far as I know. It covers keg as well as cask, with the idea of ensuring good handling from the point the beer leaves the dray to the point it is being drunk by a customer. [Click here for the BIIAB page on the qualification, which is pretty limited in information or click here for the much more informative Cask Marque page via which I booked my own course.]

The ABCQ is a “hands on” approach to keeping & serving beer, as opposed to the Beer Academy’s Advanced Course which is more oriented around the drinking the beer in the glass end of things, communicating about beer, and details of beer production and style. The ABCQ has some overlap but is mostly style/taste-agnostic – less interested in the beer itself beyond basic factors of quality. Beer is beer – you can have this beer in keg, cask, and “packaged” (bottle/can) varieties – the ABCQ is all about getting that beer from container to glass in good form.

I did the ABCQ course and exam on Monday November 11th at a cost of £115.80 (inc-VAT). It was a fun day out – and I came away with another certificate to add to my collection. Well, it arrived a couple of weeks later but I was pretty confident I’d “passed”. When the results arrived I found I’d managed 100% in the 30 question multi-choice exam, but I’d not say that is any great feat & I imagine 100% scores are common. (I also come at this from a position of having a decent base of knowledge and practice in the subject matter.) [Para added as update on 28/12/2014.]

My simple summary of this 1-day course, aka TL;DR, is: every pub should have at least one person who has done it. In an ideal case you should not be allowed in the cellar without having first done this course (“cellar license”?). It is a good and worthwhile thing to do. There are folk out there with a higher level of knowledge and experience already who simply don’t need it… but they’re probably few and far between and I suspect some who think they’re “it” in the cellar are not as “it” as they think.[1] (Even if just a case of “going through the motions” – much like farm kids who’ve been competently driving since they were 8 still needing a license to drive on public roads. Usually they’ll be practically competent – they may have a good grasp of the rules of the road too, but the license ensures they cover the rules as well at the practice.)

The ABCQ provides template methodologies that I agree will almost always work in “the usual case”, and identify what to do (or who to call) in several outlier cases. A motivated staff member who has done this ‘award’ and paid attention should always be able to serve beer in good form. If you can get hold of a copy of the “Profit Through Quality” handbook (see right) that goes with the course (which can be found online, after you lie about your age) then you can review all the material the course covers.

I also think that the cost of £115.80 makes it particularly accessible and I think it would be a useful “feather in your cap” if you’re keen on a career behind the bar and in the cellar (even if just to get you through uni for a few years, say). Along with train travel it cost me less than £200 in the end – including an evening out in London having some beers. If you’re lucky you’ll live closer to one of the several training locations – if luckier still you can talk your employer into paying it for you! It is worth their while, worth yours, and good for the industry all-round. [Para added as update on 28/12/2014.]

There are some ‘howevers‘, however. My more lengthy take on it continues below, because I do have some criticisms that are probably more justifications for creating an “advanced” type course that needs some more time and goes a bit further.

The ABCQ glosses over some details that I think need more explaining to give staff a enough of an understanding of beer to get it right all the time. The training stops short of providing enough knowledge for staff to solve issues, work with modern beer diversity, and understand keg beer. In essence it is a fantastic base-level that should work perfectly for someone working in a huge pub-chain[2]. Which, as on the day, is presumably where most of the demand for the ABCQ comes from. It definitely provides a good basis for folk who’re new to the industry to start out from.

The ABCQ is only a day long – it probably does the best it can with the time available. What it needs is another day (or two) to go deeper with…

- More detail on cask ale. “Secondary”/”conditioning” are glossed over somewhat, presumably in the name of brevity (it is only 1 day after all). So a technique is given that will almost always work but doesn’t adequately justify itself or allow for some of the common quirks of cask ale. I guess this is where cask becomes an on-the-job acquired “art” rather than a science – but it is an art with some basic technical foundations that can be taught.

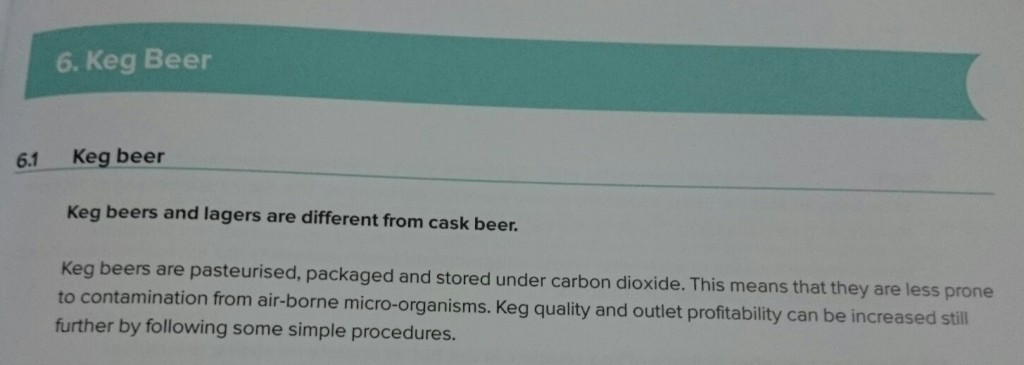

- More (any!) real detail on keg dispense. In the world of the ABCQ all you need to know about keg beer is how to attach/detach coupler, clean lines, ensure coolers are topped up (advanced material). What gas you use and what pressure you use is a matter for “Technical Services” (you need to know not to get your gas mixed up though). This, of course, very much fits the UK world where nearly every keg tap in nearly every pub is a tied line.

- Variety in storage of ‘packaged’ beer (cans/bottles). They’re something kept in a fridge. When in the specialist beer world you need to be more careful in my opinion. I just confused matters (took them off track) when I suggested you need to serve bottled beer at an appropriate temperature. (If I had a pub I’d want at least 2 fridges set at different temperatures, as well as a decent bottle-store in the cellar. Yes, OK, I am a beer nerd. I’d also want adjustable inline coolers for keg!)

I think all the above is necessary to fully mesh the beer quality expectations set up by the Beer Academy Advanced Course with the serve quality standards taught by the ABCQ.

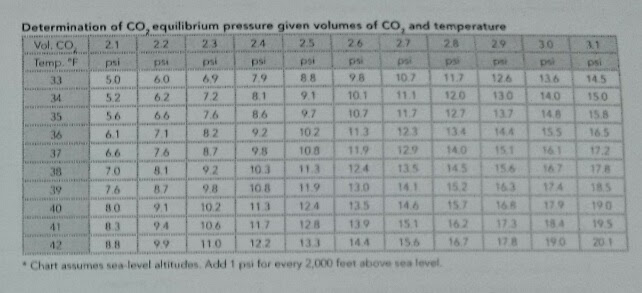

Point 2 is the one I have more issues with right at the moment. Microbrewery keg beer is becoming “big”(er), many big distributors are picking it up now. I increasingly see kegs that actually specify their target vol CO2. (Not uncommon in the international “craft scene” I gather?) Here we’re heading into Certified Cicerone territory. One thing you definitely do not see in doing the ABCQ is a pressure/temperature/volCO2 table. In fact touching the pressure gauge is a big no-no. Yes, used incorrectly they can create very dangerous situations, which is why I think a bit more should be taught about them, ASAP – especially with the increased prevalence of KeyKeg. (Brewer tells staff to up the pressure, keg line has no gauge… what next? This has happened to me twice in the last 6 months in places where a brewery or cellar services company has fitted “craft beer lines”.)

Basically the ABCQ isn’t “craft ready” (no surprise of course) and if you want to be able to seriously treat keg “right” in your bar I’d suggest you poach staff from BrewDog who’ve done the Certified Cicerone. (Or get existing staff on-track to do it themselves, there are occasional UK exams now.) I think that for the UK beer world there needs to be an A(dvanced)ABCQ that is an extra day or two of instruction and goes into some of the finer details.

Alternatively we (the “craft beer industry”) could take what Cicerone have and adapt it to create out own British Cicerone (differently named I guess, since Cicerone is TMed!) My own studies of the Draught Beer Quality Manual [pdf] show it to be not quite right for general UK use. The main factors it does not cover that are standard in the UK are: 1) inline chillers, 2) keeping kegs at 12C (DBQM temp tables go to 5.5C max), 3) use of flow-restrictors rather than lots of 3/16 line to battle fobbing (increase “line resistance”).

My intention isn’t to knock the ABCQ, I *did* learn things as a result of doing it. I’m no expert, I’m a novice trying to work my way towards becoming a technical expert. (Ask me again in a decade perhaps.) I won’t itemise all the new little facts I picked up – the area that was mostly new to me was on ‘beer clean’ glassware and correct glasswashing methods and chemicals. The quick tour of Fuller’s brewery was a nice bonus. There was also very good quality beer available on tap, naturally as part of the course was hands-on keg and cask handling to connect up and pull through for dispense. (The Firecracker in cask and the Frontier “craft lager” in keg – both beers I enjoyed on the day.) I’ve done exams before after drinking beer, but the ABCQ exam was the first one I’ve ever done *whilst* sipping a pint.

The next UK qualification I’d like to do is the “Technical Certificate in Cellar Service Installation and Maintenance” – but that’s nearly £1k of spend so I don’t know if it’ll happen any time soon. It will cover some of the gas and equipment handling and may bridge some of the technical-end gap between the Certified Cicerone and the ABCQ perhaps. It will be total overkill for cellar staff, but I build keg dispense setups for myself so it will be relevant to me.

Perhaps I’ll have an opportunity to do the Certified Cicerone first? Quite keen to do it, but a bit daunted by having to remember a bunch of BJCP style guide gumph.

[1] In “the field” I’ve found one chap who was instructed by the previous “expert” cellar person to peg casks that are being used with vertical extractors. That may be one of the most ridiculous example I’ve got, but it goes to show the crazy stuff I find going on in cellars. Issues of cleanliness are my primary personal concern. Folk not properly cleaning cask taps, re-using manky hard spiles, not cleaning keystones & shives, etc… the ABCQ teaches students to give everything a proper scrub & clean at least. I go one step further by preference and have a spray-bottle of a sanitiser handy too. This seems especially important to me under their ideal guidelines of: vent-and-tap-immediately & serve-when-ready. If there are nasties on the shive, spile, keystone, or tap this method gives all the more time for them to wreak havoc in your tasty beer.

[2] The BIIAB ABCQ course and material are brought to you by the following… (Masrton’s?!) which makes one ponder the motivations of the course and it’s “good tied pubs/lines” nature versus being perhaps not quite comprehensive enough to be so useful to the free trade. (Clenaware Systems market ‘Renovate‘ which is specifically pushed as a glassware silver bullet in the course… my cynic alarm is properly flashing now.)